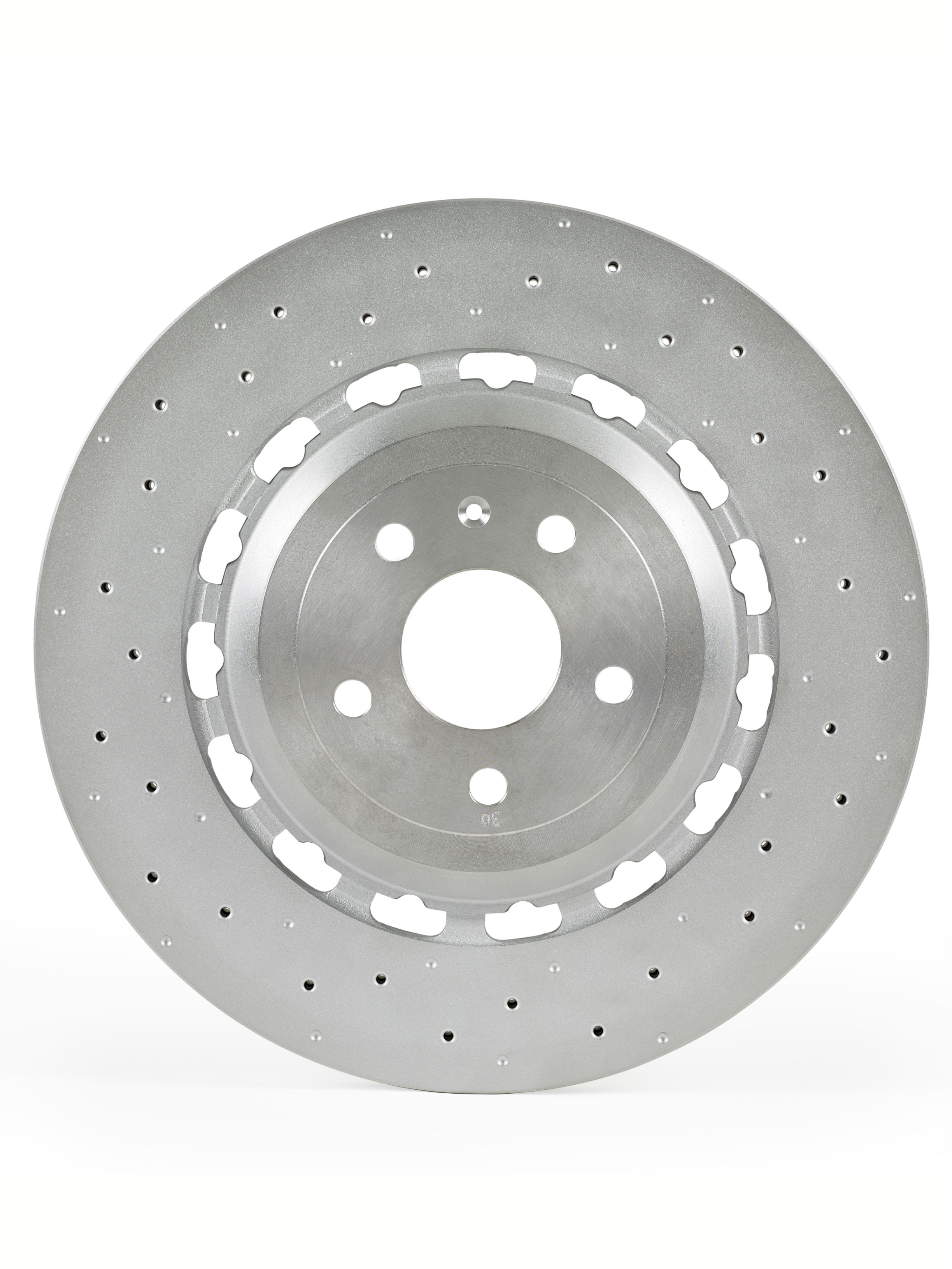

This disc has many benefits: weight reduction by about 20% (compared to an integral disc of the same dimensions), greater comfort, reduction of corrosion and wear and better performance of the components.

A fundamental characteristic of this type of disc is the cast iron braking band and the aluminum bell, which combine the advantages of the way cast iron performs at high temperatures with the lightweight properties of the aluminum.

The innovation consists in the way the two materials were combined into a single component and in the performance of the disc itself; in fact, it is an integral disc at low temperatures and it performs as a floating disc at high temperatures, when top performance is demanded and the disc tends to deform.

The dual-cast brake disc also meets the need of drastically reducing weight, combined with an improved braking feeling in the most extreme uses and an increase of resistance to fatigue at high temperature.

This allows for a significant reduction in transitory and permanent thermal deformations. The former occur typically while braking, when the disc reaches high temperatures; the latter, on the other hand, are the leading cause of vibrations in the vehicle.