Adrian Newey is the design genius at Red Bull Racing who has changed the way we perceive Formula One. The English engineer who shares the same birthplace as Williams Shakespeare, Stratford-upon-Avon, has in recent years made a unique contribution to the GP single-seater technique of which the general public is mostly unaware. In his view, every part of the car must improve performance. The braking system, for example, should not only be used to slow down the vehicle in as short a distance as possible on turns, but must contribute to serving at least two more functions: warming up the tyres so that they reach the right temperature already on the first qualifying or race lap as well as improving aerodynamics and reducing drag.

A DIFFERENT BRAKING SYSTEM FOR EVERY F1 TEAM

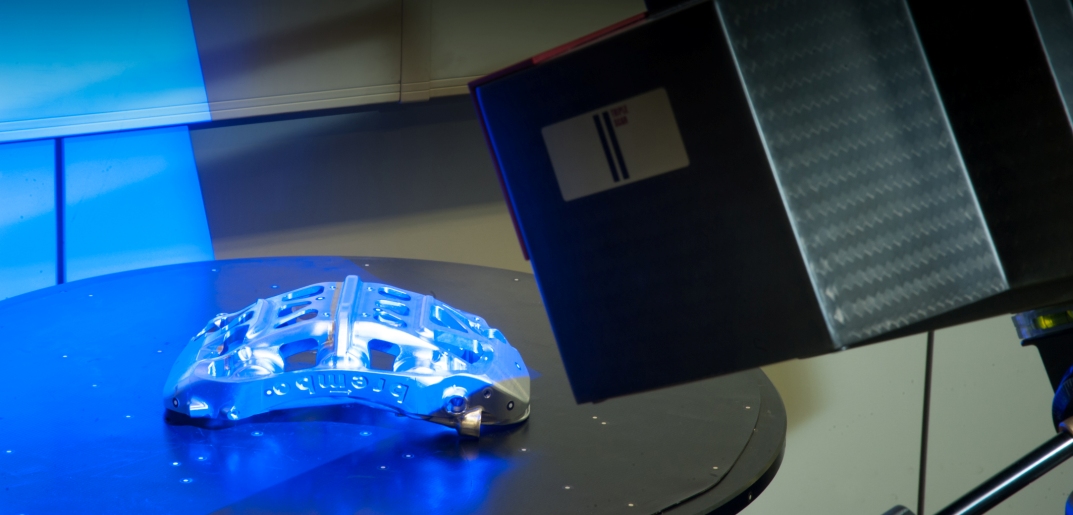

Brembo, the world leader in anything to do with brakes, has chosen Motorsport as a test bench for research: the innovation that comes from racing always has an effect on standard products. The Bergamo-based company has six teams in Formula 1. To meet the designers' demands, supplying Formula 1's best braking systems is simply not enough: “During a championship", Mauro Piccoli, Brembo Racing Director, explained, "there can be as many as three or four changes to the carbon discs that involve reducing the rear disc diameter, developing a new vent or modifying the braking surface so that the discs can be used at different temperatures. We develop a couple of solutions when we supply the braking systems, whereas the changes are requested by the teams: every F1 team, including the smallest ones, has its own bespoke design which means that stock parts are not possible”.

12 HOURS OF MACHINING FOR A THOUSAND-HOLE DISC

Just one carbon thousand cooling hole disc requires approximately 10/12 hours of boring. For each type of circuit, there are also discs with heat dissipation holes that may vary in size and design. Every braking system is the result of customisation and an in-depth study that involves the team technicians who work in close contact with the Brembo Racing team now consisting of 180 specialists.

THE DYNAMIC BRAKE TESTER IS A “MINI WIND TUNNEL”

Research has therefore become more extreme: ever since tests on the track during the racing season have been banned, development work must be carried out on test benches. Brembo Racing, which has always been very sensitive to its teams' demands, was the first to use two dynamometer benches which it jealously keeps a secret in its technologically advanced factory in Curno. One, in particular, is a “gem” that is envied by virtually all the Formula 1 circus. What exactly is it? It is a sort of mini “wind tunnel”, even if the term is incorrect, where the cooling air flow can be modified by simulating exactly what is happening on the vehicle in terms of flow. It is a fascinating but virtually unheard of topic.

BRAKE DUCTS, MASTERPIECES OF… MODERN ART

We have gradually seen carbon brake ducts appear on Formula 1 wheels that have become increasingly more complicated with air vents, flaps and flow control devices that have acquired a much more sophisticated design (they are true masterpieces of modern art) because the aerodynamic engineers have seen that by clearing air of the turbulence that is generated as the tyre rotates, they can reduce the drag of the single-seater or increase downforce.

THE BASKET HIDES MANY SECRETS

Since FIA regulations are very restrictive, when a line of research is found that can improve performance, it is investigated by engineers. In the world of brakes, a number of very important discoveries have been made. If the brake ducts are the result of work that can be seen, we should try and understand what influence a braking system can have in the parts that cannot be seen. The disc, caliper and hub carrier are now hidden inside a “basket” made of composite material. This is a cover that is the result of highly complex studies at the CFD which are then used on the Brembo test bench. We asked Roberto Malagoli, Testing Manager, for many years one of the Brembo faces in the Circus paddock who is now responsible for the “mini tunnel” in the Testing and Validation Department, for more information.

THE COMPLETE CORNER IS ASSEMBLED ON THE BRAKE TEST BENCH

“It is a test bench that can be used to simulate the functioning of a full braking system on 1 corner and analyse all its implications. The teams book it for a week of exclusive tests. They come here and bring their material with them. They assemble their “corner” complete with suspension and wheel on the dynamometer bench”. Which tests are performed? “First of all, normal braking tests by simulating a real race using telemetric data: temperature, brake torque and cooling are all checked. All this is electronically controlled using special programs. In actual fact, once the teams have found a work base, they experiment with new solutions: they assemble baskets with closed or more open mesh, modify the ducts and introduce small aerodynamic elements”.

HOT AIR FROM THE BRAKES IS ALSO USED TO… WARM UP THE TYRES

Obviously by making one change at a time just like when testing in the wind tunnel. Until quite recently, the idea was to expel hot air from the brakes as quickly as possible to protect the braking system. Nowadays, on the other hand, designers prefer to select the incoming (there are vents that supply the disc and others for the calliper) and outgoing air flows. If the wheel has to be heated to bring the tyres to the right temperature, baskets are used that have an opening near the disc so that the boiling hot air (on bends at top speed the temperature can reach 1000 degrees!) is sent where it is needed on the wheel and is not dissipated. Ferrari, for example, uses closed baskets with three teardrop-shaped openings which were round at the beginning of the season.

FOUR TEAMS DO RESEARCH AT THE FACILITY IN CURNO

Four teams use the Brembo Racing test bench on a regular basis and some have tried to reproduce the “mini tunnel” in their own factories understanding the strategic importance of this delicate part of the single seater.

“There is a powerful fan that rotates at a constant speed on the bench", Malagoli went on, "then there is an electric motor controller that is controlled by software that increases or reduces the air flow towards the complete “corner” just as if it were assembled on a single-seater on the race track. The air flow is adjusted according to wheel speed. At 360 km/h the air flow reaches 100 m/s, but the air that enters the ducts undergoes resistance that reduces the air flow and may drop to one third: the flow speed therefore drops to only 30 m/s. That is why pressure is measured at the air input, in the ducts and in various parts of the basket. The system must be efficient because if it is not, it will need larger vents that ruin the aerodynamics".

CI PERFORATED HUBS ARE USED TO IMPROVE AERODYNAMICS

Red Bull Racing, Ferrari, Williams and McLaren use perforated hubs on some tracks (ones that are not as fast as others): air from the brakes is directed towards the centre of the wheel where less turbulence is created.

The hot air flow that comes out of the wheel rim is used to direct the air that is diverted by the front wing shield so that it avoids the “wall” of the front tyre: if the air flows are well synchronised, the flow can be directed towards the rear diffuser by increasing downforce. This is very difficult and requires extensive simulation studies at the CFD and practical tests on the Brembo test bench to confirm the work.

THE RESEARCH NEVER STOPS…

Alongside Malagoli and the performance engineer and mechanics that assemble and dismantle the individual parts, there is also an aerodynamic engineer who, by reading the values measured by the sensors on a computer, is able to assess the increase in efficiency of the … braking system. “I have noticed that we often look for certain results and find others which are not the same as the computer simulations", Malagoli concluded, "and this opens up new scenarios to be explored …”. And Brembo Racing will be ready to implement its braking systems using all these innovations and demonstrate the multidisciplinary expertise of its technicians: F1 is the pinnacle of automotive technology and anyone who works in this field cannot afford to rest on their laurels…