The evolution of Brembo brake discs in racing

Since its debut in the world of motorcycle racing in the early 70s to the present day, Brembo used four different types of material to produce brake discs. From plasma coated aluminium discs used in the course of 80 years to reduce the weight in the 125 and 250 classes to the floating discs with disc carrier in cast aluminium and disc rotor in cast iron screwed on the disc carrier up to the floating discs with aluminium disc carrier and stainless steel disc rotor. In early 90s, a new material with revolutionary features made its appearance. This is carbon and it was then used to manufacture the discs of premier class bikes, the first for the 500 class and then for MotoGP and briefly for the 250 class.

The brake disc

Carbon discs allow a considerable decrease in weight on unsprung masses, significantly reduce the gyroscopic effect improving bike handling and provide performance far superior to those offered by steel counterparts. However, they have a flaw: they are unable to brake effectively until they reach the correct operating temperature; which is why the pilots use the warm-up lap and the first bends after the start to bring the discs at the right temperature. To this date, in Moto GP, in case of rain, meaning that weather conditions do not allow the correct temperature range of operation to be achieved, the brake discs used are still made of steel. Even with low temperatures, however, but in the absence of water, carbon discs still remain the solution of choice, perhaps with standard band (see below), with any needed use of protective covers produced by the teams to raise and maintain their operating temperature even when not braking.

The disc type

During the last season of 2014 the Regulation on measures of front disc brakes made of carbon in the MotoGP class was amended. Up to now, the rules allowed two formats of front discs: 320mm, used in almost all tracks and 340mm, mandatory for Motegi and optional for Barcelona and Sepang. This modification allows 340mm discs to be used on tracks (where the use of 320 is still allowed), while remaining mandatory for Motegi.

The brake pads

The main characteristics of the Brembo carbon brake pads used in MotoGP championship racing are high friction and constant effciency, especially with high disc temperatures, but still falling within the correct range of use. These characteristics guarantee an excellent and uniform braking for the duration of the competition, making it less likely for fading to occur. Above the maximum temperatures, the friction coeffcient for carbon may change, triggering the fading effect with consequent decay of braking performance and sudden increase in wear of carbon disc and pads.

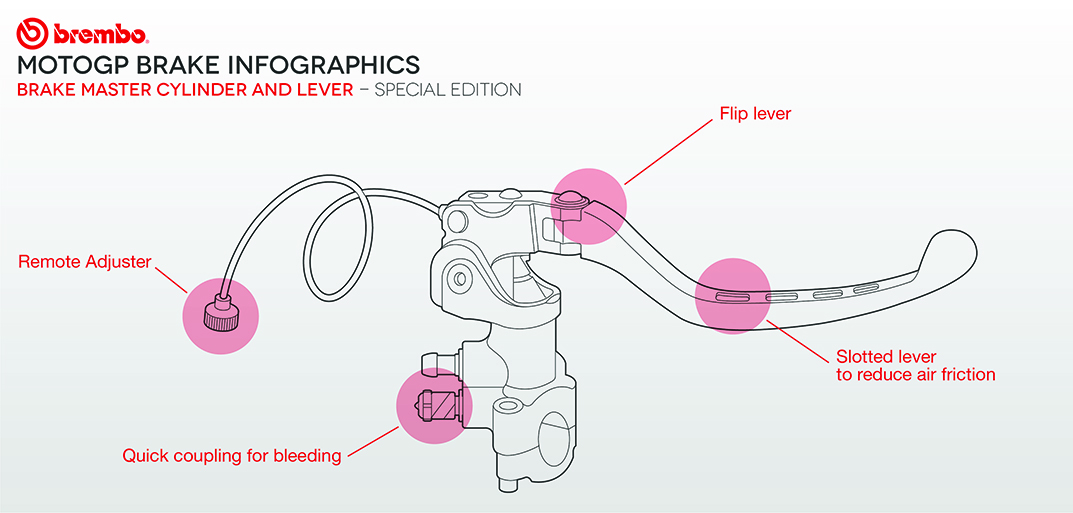

Brake master cylinder and lever

The history of the radial brake master cylinder begins in 1985 when the first Brembo registered the first patent idea that was destined to revolutionise brake systems. The idea was initially adopted in the Racing, where issues of limited space on race bikes require adamant research for more compact solutions. The new solution, in addition to reducing the overall dimensions, was able to improve the ergonomics of the driver, making lever actuation more effective. This structural arrangement, among other benefits, also allowed designing of the brake master cylinder with the aim of optimising the hydraulic and mechanical interactions, in order to improve the performance of the product. In 1986, the radial brake master cylinder already took to the track, on board the Yamaha YZR OW 81 of the American Lawson who, that year, won the 500 class championship. The American pilot immediately appreciated the high linearity of response: this convinced Brembo to further develop the idea, introducing new seals and enhancing the enhancing the adjusting device of the lever distance from the handlebar.

The brake caliper

The Brembo 4 piston monoblock calipers for the Moto GP are drawn from a single block of aluminium-lithium material. The shape of the caliper body is designed in order to optimise the mass/stiffness relationship whilst the surface is nickel plated. One of the most obvious differences compared to the calipers fitted to road bikes is the presence of “quick couplings” for purging and feeding that allow for rapid caliper replacement or bleeding between test sessions or during the same session.